Products

Solution

- Cosmetic application

- Chemical application

- Alkyd resin production line equipment

- Acrylic resin production line equipment

- (PU) polyurethane production line equipment

- Epoxy resin production line equipment

- Polyol production line equipment

- Silicone oil, varnish production line equipment

- Hot melt adhesive production line equipment

- Modified rosin resin production line equipment

- Adhesive production line equipment

- Water reducing agent production line equipment

- LED raw material mixing production line equipment

- Waterborne acrylic production line equipment

- Waterborne PU resin production line equipment

- Coating application

- New energy application

- Food application

- Pharmaceutical application

- Internet of Things application

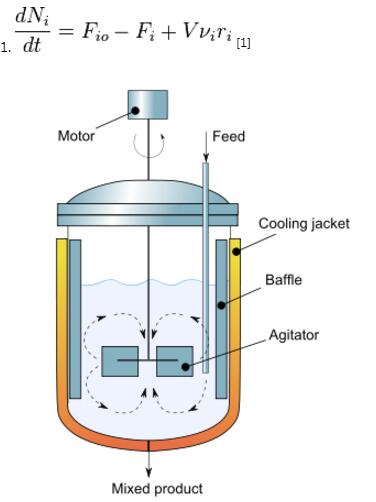

stoichiometric coefficient. The reaction rate, r, is generally dependent on the reactant concentration and the rate constant (k). The rate constant can be determined by using a known empirical reaction rates that is adjusted for temperature using the Arrhenius temperature dependence. Generally, as the temperature increases so does the rate at which the reaction occurs. Residence time,

stoichiometric coefficient. The reaction rate, r, is generally dependent on the reactant concentration and the rate constant (k). The rate constant can be determined by using a known empirical reaction rates that is adjusted for temperature using the Arrhenius temperature dependence. Generally, as the temperature increases so does the rate at which the reaction occurs. Residence time,  , is the average amount of time a discrete quantity of reagent spends inside the tank.

, is the average amount of time a discrete quantity of reagent spends inside the tank.